-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- ROBOTICS SPECIAL MACHINERY

- FOUNDRY PATTERN MAKING

- AUTOMATED WINDOW MANUFACTURING ROBOTIC ARMS AND ROBOTICS

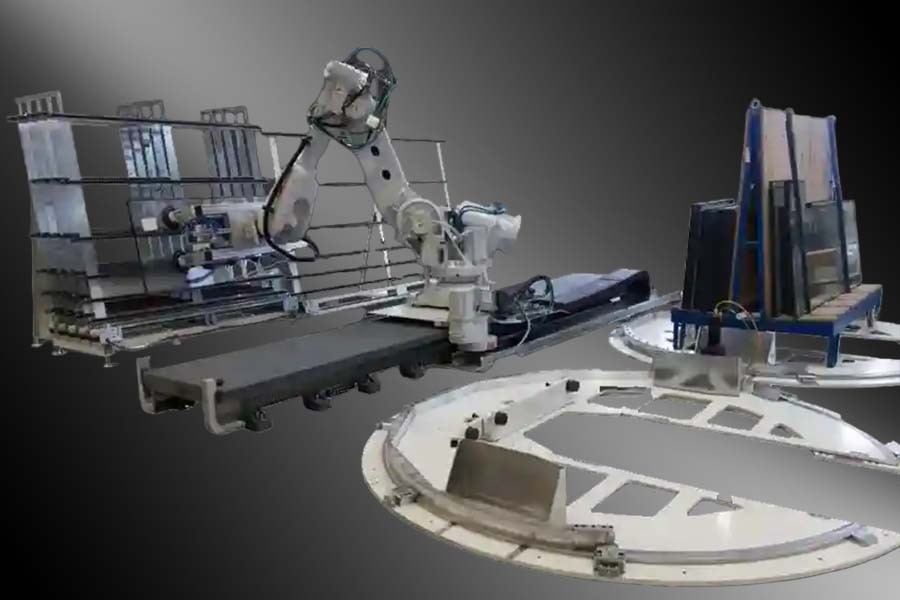

The Future of Window Manufacturing: ABB Robotic Arms, Siemens Hardware, Festo and Evomatec Algorithms Revolutionize the Industry

In a world where technology is transforming various industries, window manufacturing is no exception. The introduction of ABB robotic arms, Siemens hardware, and Evomatec GmbH algorithms into the manufacturing process has significantly improved the efficiency, precision, and quality of products. In this blog post, we delve deep into the world of robotics in window manufacturing, showcasing how these innovations are changing the industry and why they are essential for the future.

The Evolution of Window Manufacturing with Evomatec

Traditionally, window manufacturing was a heavily manual process. From cutting the glass to processing the frames to assembly, each step required manual skills and careful handling. While this method delivered excellent craftsmanship, it was also time-consuming and prone to human error.

With the introduction of automation and robotics into manufacturing, a new standard has been set. ABB robotic arms, Siemens hardware, and Evomatec algorithms can perform tasks faster and with consistently high precision. This not only reduces production time but also minimizes errors and waste, leading to sustainable and cost-effective manufacturing.

ABB Robotic Arms in Window Manufacturing

ABB is a global leader in industrial robots and automation solutions. ABB's robotic arms are the heart of modern automation in window manufacturing. These advanced machines are capable of performing a variety of tasks, including:

Glass Cutting: Using laser cutting technology, ABB robotic arms can precisely and quickly cut glass sheets to the desired dimensions. This ensures exact edges and reduces the risk of breakage.

Frame Assembly: ABB robotic arms can assemble frame components with the highest precision. They are able to maintain consistent quality standards and can efficiently implement complex designs.

Glazing: Placing glass panes into frames requires accuracy and care. ABB robotic arms can perform this task repeatedly and precisely, minimizing the risk of damage.

Sealing: Sealing windows is crucial for their insulation capability. ABB robotic arms can apply sealant evenly and tightly, resulting in better insulation values and longer durability.

Siemens Hardware in Window Manufacturing

Siemens hardware plays a crucial role in controlling and monitoring manufacturing processes. Siemens offers a wide range of automation solutions that seamlessly integrate with ABB robotic arms to ensure smooth and efficient operation.

Control Systems: Siemens control systems, such as the SIMATIC S7, provide precise and reliable control over robotic arms and other machines in the production line. This allows for seamless coordination and synchronization of various processes.

HMI (Human Machine Interface): Siemens HMI solutions, like SIMATIC HMI, enable user-friendly monitoring and control of robots and machines. This makes it easier for operators to interact with the system and make adjustments.

Sensors and Actuators: Siemens offers a variety of sensors and actuators that can be integrated into the manufacturing process to ensure accurate monitoring and control. These components contribute to quality assurance and process optimization.

Evomatec Algorithms in Window Manufacturing

Evomatec GmbH specializes in developing advanced algorithms that further enhance the performance of automation systems. Their algorithms optimize processes and enable intelligent adaptation to changing production requirements.

Optimized Process Control: Evomatec algorithms continuously analyze production data and adjust the settings of robotic arms and machines to ensure maximum efficiency and precision.

Error Detection and Correction: Using machine learning, Evomatec algorithms can detect potential errors early and implement corrective measures before major issues arise.

Energy Efficiency: Evomatec algorithms optimize the energy consumption of production facilities, leading to more sustainable and cost-effective manufacturing.

Benefits of Combining ABB Robotic Arms, Siemens Hardware, and Evomatec Algorithms

The integration of ABB robotic arms, Siemens hardware, and Evomatec algorithms in window manufacturing offers numerous benefits:

Increased Productivity: ABB robotic arms can work around the clock without fatigue. Combined with Siemens' precise control systems and Evomatec's optimizing algorithms, production capacity is significantly increased and lead times are shortened.

Consistent Quality: The automation solutions from ABB and Siemens, supported by Evomatec's intelligent algorithms, deliver consistently high quality as they execute precisely programmed movements and eliminate human errors.

Cost Savings: By reducing waste and increasing efficiency, companies can lower their production costs and become more competitive.

Flexibility: Modern ABB robotic arms are programmable and adaptable. Combined with Siemens' versatile hardware and Evomatec's adaptable algorithms, they can quickly switch to different product types and designs, making production more versatile.

Safety: Automation reduces the need for manual intervention in hazardous areas, decreasing the risk of workplace accidents.

Future Prospects of Robotics in Window Manufacturing

The development of robotics is not static. With advances in artificial intelligence (AI) and machine learning, robots are becoming more intelligent and adaptable. In the future, ABB robotic arms in window manufacturing could not only perform pre-programmed tasks but also make autonomous adjustments and optimized production decisions.

Furthermore, collaborative robots (cobots) could be integrated into manufacturing to work even more closely with human workers. These cobots could take over dangerous or repetitive tasks, allowing human employees to focus on creative and more complex activities.

The integration of ABB robotic arms, Siemens hardware, Festo and Evomatec algorithms in window manufacturing has revolutionized the industry. It offers significant advantages in terms of efficiency, quality, and costs while improving working conditions and enhancing safety. Companies that adopt these technologies are better equipped to meet market challenges and deliver high-quality products to their customers.

The future of window manufacturing lies in automation. Through continuous innovation and investment in robotics, companies can increase their competitiveness while producing sustainable and high-quality window products. The combination of ABB robotic arms, Siemens hardware, and Evomatec algorithms has opened the door to a new era of window manufacturing – one that is more precise, efficient, and future-oriented.

TAGS

- AUTOMATED WINDOW MANUFACTURING ROBOTIC ARMS AND ROBOTICS

- Robotic Arms Window Manufacturing

- Robotics Window Production

- Automated Window Fabrication

- Window Manufacturing Robots

- Glass Cutting Robots

- Frame Assembly Automation

- Window Glazing Robotics

- Sealing Window Automation

- Productivity Window Manufacturing

- Quality Control Window Production

- Cost Efficient Window Manufacturing

- Safety Window Production

- Future Window Manufacturing

- Artificial Intelligence Window Production

- Cobots Window Manufacturing

- ABB Robotic

- Siemens

- Festo

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL