-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

product

- Home

- product

- ROBOTICS SPECIAL MACHINERY

- FOUNDRY PATTERN MAKING

- TORQUE TESTING MACHINES FOR CAR SEATS

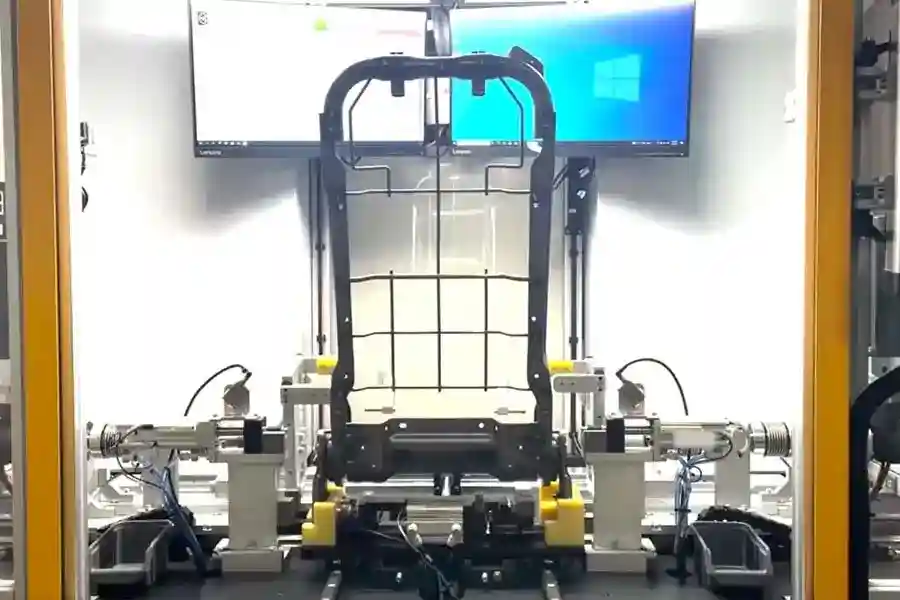

Torque Testing Machines for Car Seats: Precision and Reliability by Evomatec

In the modern automotive industry, the safety and comfort of vehicle occupants are of utmost importance. A crucial component of this safety and comfort is the car seat, which must undergo rigorous testing to ensure it meets the high standards of the industry. One of the most important tests that car seats must pass is the torque test. These tests measure the torque and structural integrity of the seats under various conditions. Evomatec, a leading company in special machine construction, specializes in the production of high-precision torque testing machines for car seats. In this blog post, we will explain the significance of torque tests, the functionality of Evomatec's torque testing machines, and the benefits they offer to automotive manufacturers.

The Importance of Torque Tests for Car Seats

Torque tests are crucial for ensuring the quality and safety of car seats. These tests simulate the loads and torques that a car seat is subjected to during use. Various aspects are examined, including:

- Structural Integrity: Torque tests help ensure that the seats maintain their shape and function under various loads. This is important for guaranteeing the safety of occupants.

- Comfort: Besides safety, comfort is also a key factor. Torque tests help ensure that the seats retain their ergonomic shape even after prolonged use, without compromising driving comfort.

- Durability: By simulating long-term loads, torque tests can evaluate the lifespan of the seats and ensure they withstand daily wear and tear.

- Safety Features: Modern car seats often come equipped with additional safety features like airbags and seatbelt pre-tensioners. Torque tests ensure that these features work reliably under realistic conditions.

Evomatec: Leading in the Production of Torque Testing Machines

Evomatec has made a name for itself by developing innovative and customized machine solutions for various industries. In the field of torque testing machines for car seats, Evomatec offers a wide range of solutions tailored specifically to the automotive industry’s needs. Evomatec’s machines are known for their precision, reliability, and user-friendliness.

-

Consultation and Concept Development

- The process begins with detailed consultation and concept development. Evomatec works closely with automotive manufacturers to understand their specific requirements. This close collaboration allows Evomatec to develop customized solutions that are precisely tailored to the customers' needs. State-of-the-art technologies and innovative approaches are considered to find the best possible solution.

-

Design and Development

- Following concept development is the design and development phase of the torque testing machines. Evomatec has an experienced team of engineers and technicians who use advanced CAD software and simulation tools to design precise and efficient machines. Special emphasis is placed on quality, reliability, and durability.

-

Production and Assembly

- In the production phase, cutting-edge manufacturing technologies are employed to build the designed machines. Evomatec places great importance on the highest precision and quality in every step of the production process. After manufacturing, the machines are assembled, with all components carefully put together and tested.

-

Commissioning and Training

- After assembly, the machine is commissioned and extensively tested to ensure it meets customer requirements. Evomatec also provides training for operators to ensure smooth machine operation. This includes both technical training and the imparting of knowledge for optimal machine use.

-

Maintenance and Service

- Even after commissioning, Evomatec supports its customers. The company offers comprehensive maintenance and service to ensure the long-term performance and reliability of the machines. Regular maintenance and prompt support for problems ensure that the machines always function optimally.

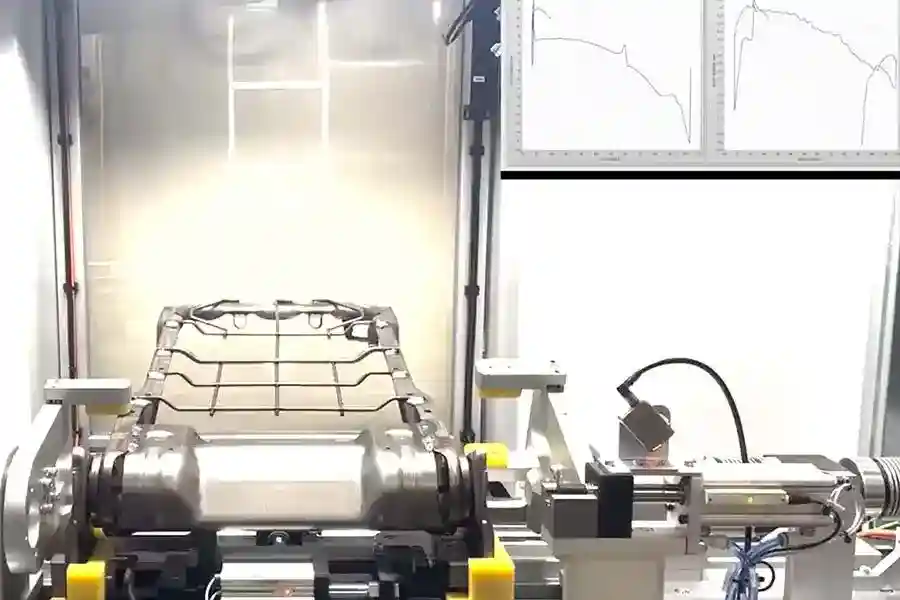

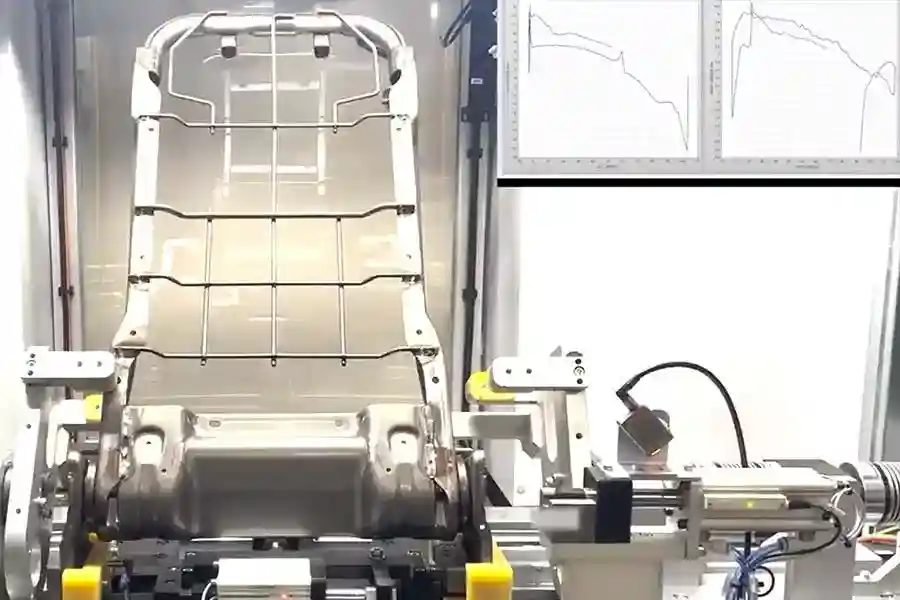

How Torque Testing Machines Work

Evomatec’s torque testing machines are highly advanced devices that enable precise measurements of the torque and structural integrity of car seats. Here are some key features and functionalities of these machines:

-

Precise Torque Measurement

- The torque testing machines are equipped with high-precision sensors that accurately measure the torque applied to the seats. These sensors can detect even the smallest changes in torque, leading to extremely accurate test results.

-

Versatile Testing Options

- Evomatec’s machines are designed to conduct a variety of tests. This includes static tests, where the torque is held constant over a period, and dynamic tests, where the torque is continuously varied. This versatility allows the seats to be tested under realistic conditions.

-

User-Friendly Software

- Evomatec places great emphasis on the user-friendliness of its machines. The torque testing machines come with intuitive software that facilitates easy operation and analysis of test results. The software offers extensive analysis options and can be easily adapted to the specific needs of customers.

-

Robust Construction

- The torque testing machines are designed for use in demanding environments. They are robust and durable to withstand the daily demands of the testing environment. This ensures a long lifespan and reliable performance of the machines.

Success Stories from Practice

Evomatec has already successfully completed numerous projects in the field of torque testing machines for car seats. Here are some examples that highlight the versatility and innovation of the company:

-

Automotive Industry

- Evomatec has developed and delivered high-precision torque testing machines for several leading automotive manufacturers. These machines are used to test the structural integrity and safety of car seats under various loads. Thanks to the precise test results, manufacturers have been able to significantly improve the quality of their seats and meet safety standards.

-

Medical Technology

- In addition to the automotive industry, Evomatec has also developed innovative solutions in medical technology. For the production of medical devices that must meet the highest precision and cleanliness requirements, Evomatec has developed customized testing machines. These machines allow the devices to be tested under realistic conditions and ensure their reliability.

-

Aerospace Industry

- In the aerospace industry, the requirements for the safety and reliability of components are particularly high. Evomatec has developed specialized torque testing machines for this industry, capable of testing the structural integrity and durability of components under extreme conditions. These machines help to meet the high safety standards of the aerospace industry.

Why Choose Evomatec?

There are many reasons why companies choose Evomatec as their partner for torque testing machines:

-

Experience and Expertise

- Evomatec has extensive experience and in-depth expertise in the field of special machine construction. The company has made a name for itself by developing innovative and customized solutions for its customers.

-

Customer Focus

- Close collaboration with customers and understanding their individual needs are at the core of Evomatec’s corporate philosophy. This enables the development of tailored solutions that precisely meet the customers' requirements.

-

Innovative Strength

- Evomatec uses state-of-the-art technologies and innovative approaches to develop precise and reliable torque testing machines. The company is always striving to continuously improve its machines and adapt to the latest industry requirements.

-

Quality and Reliability

- The highest quality and reliability are the top goals in every Evomatec project. The torque testing machines are manufactured under strict quality controls to ensure they meet the highest standards.

-

Comprehensive Service

- From initial consultation to maintenance and service, Evomatec offers comprehensive and professional support. The company stands by its customers throughout the entire process and ensures that the machines always function optimally.

Conclusion

Evomatec’s torque testing machines are an indispensable tool for the automotive industry to ensure the quality and safety of car seats. With their precision, reliability, and user-friendliness, these machines help ensure that seats meet the industry’s high standards. Evomatec is a trusted partner offering customized solutions and supporting its customers throughout the entire process.

TAGS

- Torque testing machines for car seats

- Evomatec torque testing machines

- Car seat torque testing

- Torque testing automotive industry

- Automotive seat testing

- Precision torque testing machines

- Structural integrity testing car seats

- Evomatec special machine construction

- Custom torque testing machines

- Quality assurance car seats

- Safety testing car seats

- Durability testing car seats

- Innovative torque testing machines

- Automotive testing solutions

- Custom test solutions

- Evomatec Reliable torque testing machines

- High precision automotive testing

- Car seat safety features testing

- Robust testing machines for car seats

- Advanced torque testing technology

- Automotive seat testing equipment

- User friendly testing software

- Comprehensive test analysis tools

- Customized automotive testing solutions

- Evomatec testing machinery

- Long lasting testing machines

- Automotive quality standards testing

- Car seat structural integrity

- Test machines for automotive suppliers

- Efficient testing solutions for car seats

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL