-

Company

Product

ALUMINIUM MACHINES

PORTABLE ALUMINIUM PROFILE MITRE SAW TOOL

PORTABLE COPY ROUTER MACHINE FOR ALUMINIUM PROFILES

PORTABLE END MILLING MACHINE FOR ALUMINIUM PROFILES

MITER SAW FOR ALUMINIUM PROFILES

COPY ROUTER MACHINE

END MILLING MACHINE FOR ALUMINIUM PROFILES

AUTOMATIC HYDRAULIC ALUMINIUM PROFILE CORNER CRIMPING MACHINE

DOUBLE HEAD CUTTING MACHINE FOR ALUMINIUM PROFILES

CNC AUTOMATIC SAW MACHINE FOR ALUMINIUM PROFILES

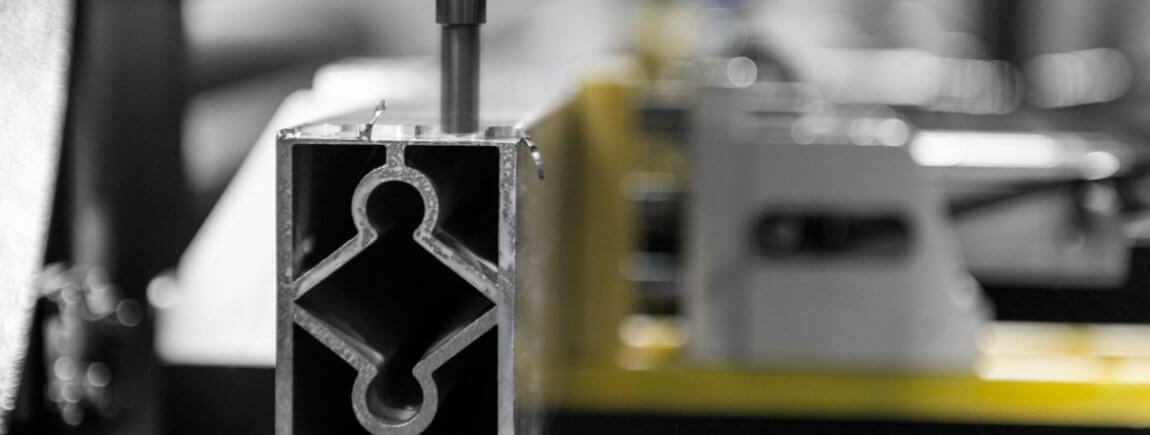

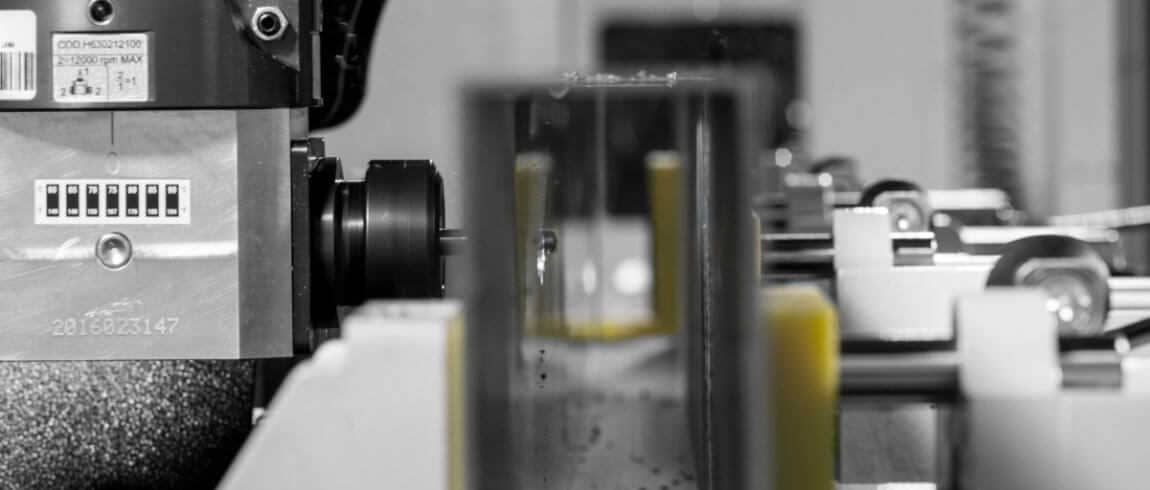

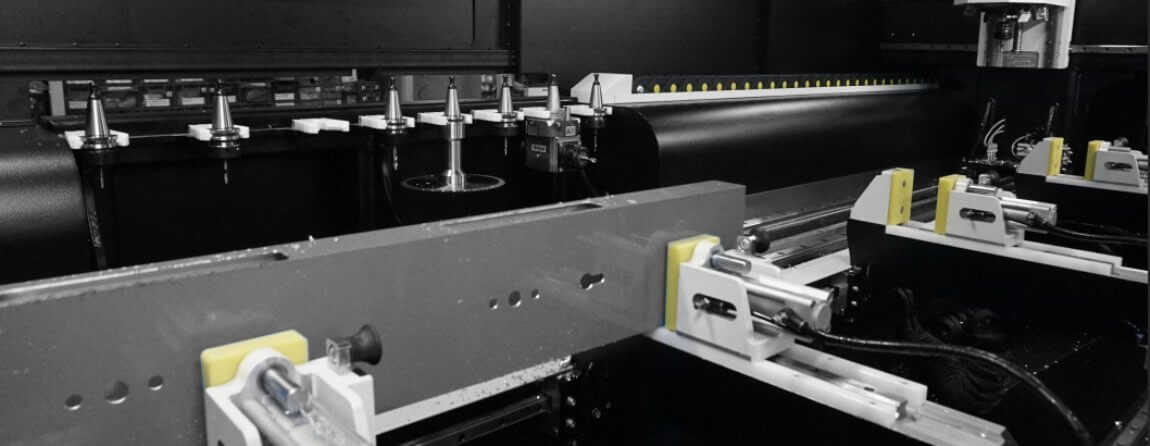

CNC PROFILE MACHINING CENTRES

ALUMINIUM COMPOSITE PANEL PROCESSING MACHINES

PVC PLASTIC MACHINES

PVC PLASTIC PROFILE MITER SAW MACHINE

PORTABLE COPY ROUTER MACHINE FOR PVC PLASTIC PROFILES

PORTABLE END MILLING MACHINE FOR PVC PLASTIC PROFILES

MITER SAW MACHINE FOR CUTTING PVC PLASTIC PROFILES

COPY ROUTER MACHINE FOR PVC PLASTIC PROFILE

END MILLING MACHINE FOR PVC PLASTIC PROFILES

PVC PLASTIC WELDING MACHINE

CORNER CLEANING MACHINE FOR PVC PLASTIC PROFILES

DOUBLE HEAD CUTTİNG MACHINE FOR PVC PLASTIC PROFILES

PROFILE MACHINING CENTRES

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINE

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORİZONTAL PRESSES

BELT GRİNDİNG MACHİNES

PİPE NOTCHİNG MACHİNES

PİPE POLİSHİNG MACHİNES

LASER CUTTING MACHINES

CNC HYDRAULIC PRESS BRAKES MACHINE

WOOD MACHINES

GLASS MACHINES

FOUNDRY AND CASTING MOLD MAKING

Service

Blog

Contact

Blog

- Home

- Blog

EM EVOMATEC FENSTERBAUMASCHINEN Germany with over 75 years of experience in mechanical engineering is specialized in the production of high-quality machines. If you want the best of the best, you are right with us. We pride ourselves on having the first machine built 75 years ago for our first customer, and this machine is still working today! Precision machines manufactured with the utmost precision by Evomatec.

Our customers include companies such as the worldwide automotive supplier Toyota. We also manufacture heavy machine parts for German machine builders. Heavy castings up to 60 tons can be cast in our factory and machined on modern Evomatec CNC equipment.

EM Evomatec has cast iron, ductile iron and cast steel (GG, GGG, GS) manufacturing and a fully equipped laboratory with EM Evomatec Fensterbaumaschinen engineers and an experienced team. The Spectral Analyzes, Microstructural Controls, Normal and Breakdown Test Facilities, the Solidcast Program for the Cooling and Flow Simulations ensure the company a successful and certified production.

The annual casting capacity is over 10,000 tons. EM Evomatec can produce up to 60 tons of gray cast iron and up to 35 tons of nodular cast iron and cast steel parts in one part of 1 kg.

EM Evomatec has increased its smelting furnace capacity, up to 60 tons per part, through the new Inductotherm induction smelting furnace investment and logistics improvement. With the single-supplier service at the induction furnaces a service quality in the highest stage was achieved.

The 3D Scanner GOM ATOS III Triple Scan with Tritop XL is used by Evomatec for his clients. No more obligatory quality and measurement controls from our clients are necessary.

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL