-

Company

Product

ALUMINIUM MACHINES

PORTABLE MITER SAWS FOR ALUMINUM

PORTABLE COPY ROUTER MACHINES FOR ALUMINIUM

PORTABLE END MILLING MACHINES FOR ALUMINIUM

AUTOMATIC MITER SAWS FOR ALUMINIUM

COPY ROUTER MACHINES FOR ALUMINIUM

END MILLING MACHINES FOR ALUMINIUM

ALUMINUM CORNER CRIMPING MACHINE

DOUBLE MITRE SAWS FOR ALUMINIUM

AUTOMATIC SAWS FOR ALUMINIUM

BAR PROCESSING CENTERS

MACHINING CENTERS FOR ALUMINIUM COMPOSITE PANELS

NOTCHING SAWS

WEDGE CUTTING SAWS AND NOTCH CUTTING SAWS

MITER SAWS FOR ALUMINIUM

PVC PLASTIC MACHINES

PORTABLE MITER SAWS FOR PLASTIC

PORTABLE COPY ROUTER MACHINES FOR PLASTIC

PORTABLE END MILLING MACHINES FOR PLASTIC

MITER SAWS FOR PLASTIC

COPY ROUTERS FOR PLASTIC

END MILLING MACHINES FOR PLASTIC

WELDING MACHINES FOR PLASTIC

CORNER CLEANING MACHINES FOR PLASTIC PROFILES

DOUBLE MITRE SAWS FOR PLASTIC

BAR PROCESSING CENTERS

GLAZING BEAD SAWS

AUTOMATIC MITRE SAWS FOR PLASTIC

METAL MACHINES

MANUAL METAL SHEET BENDING MACHINE

MANUAL BENDING MACHINES

HYDRAULIC BENDING MACHINES

NON MANDREL BENDERS

PLATE BENDING MACHINES

BORDERING AND TRIMMING MACHINES

HORIZONTAL PRESSES

BELT GRINDING MACHINES

PIPE NOTCHING MACHINES

PIPE POLISHING MACHINES

LASER CUTTING MACHINES

PRESS BRAKES

VERTICAL TURNING CENTERS

MACHINING CENTERS

WOOD MACHINES

GLASS MACHINES

ROBOTICS SPECIAL MACHINERY

Service

Blog

Contact

Blog

- Home

- Blog

- ALUMINIUM PROFILE SAW MACHINE

- DOUBLE-HEAD MITRE SAW

DOUBLE-HEAD MITRE SAW

Double-Head Mitre Saw – Scientific Consideration of a Key Technology for Profile Cutting

1. Introduction

The double-head mitre saw is a highly specialised machine tool primarily used in the processing of aluminium, plastic, and wood profiles. Its development is closely linked to the industrialisation of window, door, and façade production. By enabling simultaneous machining of workpieces from both ends, it achieves maximum precision, efficiency, and repeatability.

2. Historical Development

The origins of the mitre saw lie in traditional craftsmanship, where simple hand saws were used for wood joints at 45° or 90°. With the industrial demand for precise profile connections in construction, the first generation of double-head mitre saws was developed in the 1960s. The introduction of CNC technology in the 1980s marked the decisive step towards automation and integration into digital manufacturing processes.

3. Constructional Features

A double-head mitre saw typically consists of:

-

A machine bed with a high-stiffness design to minimise vibrations.

-

Two saw heads that can operate synchronously or separately.

-

Swivel mechanisms enabling mitre cuts between 45° and 135°.

-

A CNC control unit allowing input of cutting parameters and import of CAD/CAM data.

-

Clamping systems, usually pneumatic, for secure workpiece fixation.

4. Functionality

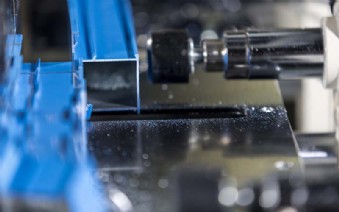

The workpiece is clamped between the two saw heads. After inputting the cutting data, the heads automatically move into position. Cutting takes place simultaneously or sequentially, ensuring dimensional accuracy within hundredths of a millimetre. Cooling systems or minimum quantity lubrication reduce friction and increase tool life.

5. Tools and Cutting Technology

The carbide saw blades used have diameters of 400–600 mm and are specifically designed for aluminium and plastic. Their tooth geometry is optimised depending on the material. Modern systems feature sensor-based monitoring to detect tool wear and automatically make adjustments.

6. Fields of Application

The double-head mitre saw is used in various industries:

-

Window and door construction: cutting frame and sash profiles.

-

Façade construction: production of precise connecting profiles for glass and metal façades.

-

Furniture and lightweight construction: processing of aluminium and wooden frames.

-

Mechanical engineering: cutting special profiles for plant construction.

7. Advantages and Scientific Evaluation

Compared to single-head mitre saws, the double-head mitre saw offers clear advantages:

-

Precision: CNC-controlled positioning significantly reduces tolerances.

-

Efficiency: simultaneous cuts reduce cycle times by up to 50%.

-

Flexibility: adaptable to different materials and profile cross-sections.

-

Sustainability: optimised cutting plans minimise waste and energy consumption.

From a scientific perspective, the machine exemplifies the synergy of mechanics, electronics, and computer science.

8. Integration into Industry 4.0

The future of the double-head mitre saw lies in networking:

-

IoT interfaces enable real-time monitoring of production data.

-

AI algorithms optimise cutting sequences and tool changes.

-

Predictive maintenance reduces downtime through proactive servicing.

-

Digital twins allow full process simulations.

9. Economic Significance

Investment in a double-head mitre saw pays off quickly due to efficiency gains. Studies show production capacities can increase by up to 60% while scrap rates decline. This makes the machine an indispensable component of modern manufacturing.

10. Conclusion

The double-head mitre saw is not just a tool but a key technology in profile processing. It combines precision, efficiency, and future viability. From a scientific viewpoint, it exemplifies the shift from traditional manufacturing methods to highly automated and digitally networked production systems.

- double head mitre saw

- double head mitre saw aluminium

- double head mitre saw plastic

- double head mitre saw wood

- cnc double head mitre saw

- automatic double head mitre saw

- industrial double head mitre saw

- precision double head mitre saw

- double head mitre saw for profile processing

- double head mitre saw for windows

- double head mitre saw for doors

- double head mitre saw for façades

- double head mitre saw for mechanical engineering

- double head mitre saw for furniture

- double head mitre saw for lightweight structures

- double head mitre saw new

- double head mitre saw used

- double head mitre saw evomatec

- double head mitre saw industry 4.0

- double head mitre saw cnc technology

GERMANY

GERMANY ENGLISH

ENGLISH FRANCE

FRANCE SPAIN

SPAIN PORTUGAL

PORTUGAL